Why I Chose Discover for ERP Requirements Gathering: A Real-World Test

Trust Discover

When it comes to selecting the right ERP system, the tools you use to evaluate options are just as important as the solutions themselves. After more than 30 years implementing, selecting, and rescuing ERP projects—especially in complex manufacturing environments—I’ve seen just how misleading most ERP selection tools can be.

Many platforms pose as “evaluation tools,” but in reality, they’re thinly veiled sales funnels, steering you toward a particular vendor’s software. That’s exactly what I wanted to avoid.

So, I tested something different: Discover—a cloud-based, unbiased ERP requirements-gathering platform.

Here’s what happened.

Putting Discover to the Test: A Real Manufacturing Scenario

To see if Discover could deliver true, vendor-neutral insights, I entered a real-world use case from my own experience: a complex, multinational manufacturing company with layered operational needs.

I used Discover to run a full business process requirements assessment.

The results?

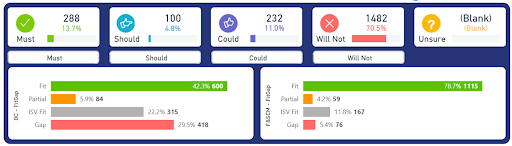

- Microsoft Dynamics 365 Business Central (BC) came back as a 43% fit

- Dynamics 365 Finance and Supply Chain Management (FSCM) showed an 81% fit

If this tool were designed to push one solution over the other, the results would have been inflated across the board. Instead,

I got honest, data-driven insights—the kind you rarely get from vendor-aligned tools or consultants.

Why Discover Stands Out from Other ERP Evaluation Tools

Most ERP selection platforms are:

- Sales-focused – Created by vendors to drive you toward their software

- Surface-level – Focused more on features than true business process fit

- Rigid – Lacking flexibility for complex industries like manufacturing

Discover flips the script by offering:

- A cloud-based interface for modern, remote teams

- Deep business process alignment, not just feature checklists

- A neutral, data-first approach with no vendor bias

It’s not about which ERP

looks best—it’s about which ERP actually

works best for your unique needs.

The Bottom Line: Trust the Process, Not the Pitch

ERP selection is one of the most important decisions a company will make—and one of the most expensive to get wrong. When your ERP system is moving to the cloud, your evaluation process needs to evolve too.

Discover isn't about hype or high-pressure sales. It’s about clarity, accuracy, and confidence.

This isn’t marketing—it’s real analysis.

If you’re serious about getting your ERP selection right the first time, start with the right foundation.

Ready to De-Risk Your ERP Project?

Let Discover help you gather requirements quickly, accurately, and without bias—so you can make a smarter ERP decision, faster.

Your ERP is going to the cloud.

Make sure your evaluation gets there too.

HandsFree ERP is dedicated to supporting clients with their ERP initiatives, enabling companies to seamlessly connect users with their ERP partners. By utilizing skilled professionals, streamlined processes, and cutting-edge tools, HandsFree ERP significantly boosts the success rates of ERP projects.