The Discover Process

ERP selection and planning

Common ERP Selection Challenges

Navigating the ERP landscape can be daunting—traditional RFPs often miss the mark by emphasizing features over true outcomes, leading to overwhelming choices with hundreds of options. At HandsFree ERP, we understand the challenges of budget and timeline risks as well as the limited expertise within internal teams. We’re here to bridge that gap and ensure your ERP project thrives!

- Unclear Business Requirements – Traditional RFPs focus on features, not outcomes.

- Overwhelming Choices – Hundreds of ERP options make selection difficult.

- Cost & Timeline Risks – Implementation often exceeds budget and schedule.

- Limited Expertise – Internal teams lack deep evaluation experience.

Business-First Approach

Focuses on business outcomes, not just features.

Realistic Estimates

Predicts costs and timelines using real project data.

Unbiased Comparisons

Ensures impartial vendor selection.

Risk Awareness

Identifies potential challenges before decisions are made.

HandsFree ERP: Smarter ERP Selection

At HandsFree ERP, we prioritize your business outcomes over mere features, providing realistic estimates based on actual project data. Our unbiased comparisons help you choose the right vendor, while our keen risk awareness identifies potential challenges early on, ensuring a seamless bridge between users and ERP partners.

ERP selection and planning

Transform Your ERP Decisions with Unbiased, Data-Driven Insights

At HandsFree ERP, we tackle ERP evaluation challenges head-on. By using a vendor-neutral tool, we eliminate overpromises and biases, providing realistic implementation timelines and capabilities. Our data-driven approach defines your business needs, ensuring you make informed decisions that lead to successful ERP projects.

- Eliminates Vendor Overpromises – Provides realistic implementation timelines and capabilities.

- Removes Bias – Vendor-neutral tool ensures objective solution comparisons.

- Data-Driven Decisions – Accurately defines business needs with precise cost and timeline estimates.

3 Steps = Fast Analysis

Our next-generation smart application offers a seamless and secure platform for onboarding your team, inputing your requirements and getting your analysis.

ONE

Onboard the Team

We will guide you through the process on how to use the online Discover Portal

Input Requirements

Fill out the requirements in the online questionnaire tailored to your own company needs at your own pace

TWO

Get Your ERP Assessment

Review your Detailed Report in MS Word and Executive Slide Summary in PowerPoint

THREE

Evaluating Microsoft Dynamics Business Central for Complex Manufacturing

Background

A manufacturing company specializing in large, highly complex, engineer-to-order (ETO) machinery sought to implement Microsoft Dynamics Business Central (BC) as its ERP solution. The business integrates standard equipment, unique components, and process manufacturing in its production and offers installation and servicing for its machinery post-production.

Challenge

As the company progressed with its BC implementation, newly hired resources began questioning whether BC was the optimal solution. Given the company’s intricate manufacturing processes, leadership required a data-driven evaluation to determine the best ERP fit and mitigate risks before full deployment.

Simple, secure, and convenient.

Relieve Your ERP Pain Today!

Whether you are in the early stages of planning an ERP project, assessing ERP software options, or actively engaged in an implementation, HandsFree ERP is your trusted team of specialists. We offer client-side advisory services and cutting-edge tools to streamline and expedite your ERP project, ensuring your success at every phase.

- Limited time offer for Microsoft Funding

- Get amazing value with an assessment that you can use right now for your planning, or use in the future.

- There is really no reason NOT to do this assessment! Unless you WANT a costly do-over later.

Train Your ERP Muscle – Join the ERP Success Academy

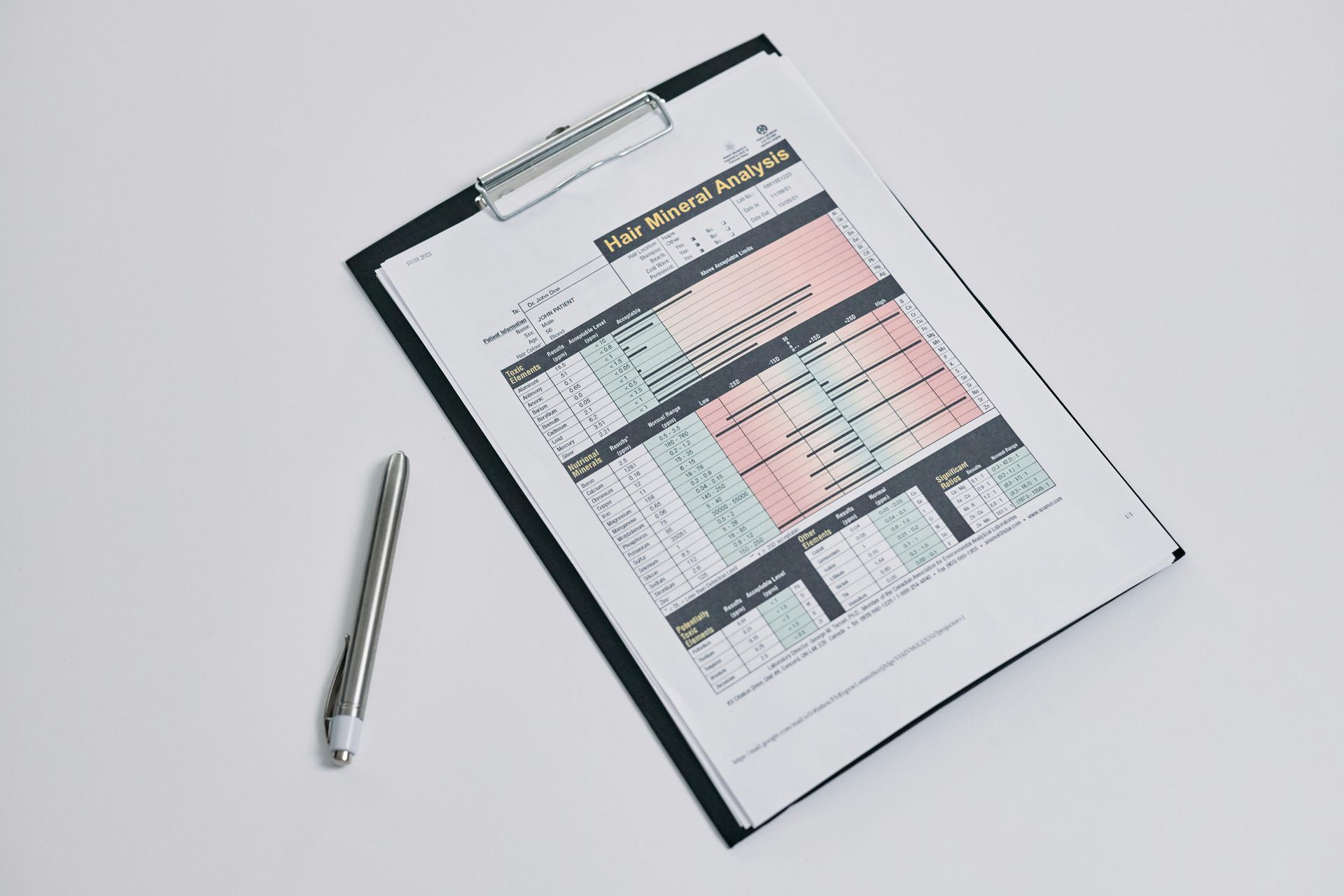

ERP Migration Clarity - Example report

Data Driven Analysis with Discover – Not Sales Opinions

HandsFree ERP assists Clients in optimizing their ERP selection process with an advanced cloud-based requirements gathering tool.

Learn more details about the GYDE365 Discover process

Top 10 FAQs for the GYDE365 Discover Process

What is Discover, and how does it help with ERP selection?

Discover is a cloud-based requirements gathering tool designed to help businesses quickly and efficiently assess their ERP needs. It moves beyond traditional ERP software feature lists and consultant-driven approaches, focusing on core business requirements to ensure a better ERP fit.

How is Discover different from traditional ERP selection methods?

Traditional methods rely on free, shallow tools that promote a specific product or expensive consultant-led projects that can take months and cost tens and hundreds of thousands of dollars. Discover sits in the middle—it’s data-driven, unbiased, and structured, allowing businesses to identify what they need without unnecessary complexity.

What kind of businesses benefit from using Discover?

Any company considering an ERP transition, whether moving from Microsoft Dynamics GP, AX, NAV, SL, or another legacy system or evaluating cloud-based ERP solutions, can benefit from Discover. Discover helps organizations in finance, procurement, HR, operations, and other departments align their business needs with the right ERP system.

How long does it take to complete the Discover process?

Most organizations complete the Discover survey in 2-3 weeks with just 20-30 minutes of daily effort. The tool streamlines the process, eliminating the need for drawn-out consulting engagements.

What types of business requirements do Discover cover?

Discover organizes business requirements into functional areas, including the General Ledger, Accounts Payable, Inventory, HR, Procurement, and more. Additionally, business requirements can be “flipped” into a critical business workflow view, such as “Order to Cash,” and how they should function or flow in a modern ERP system. This provides an insight not available in traditional “needs lists”.

Can multiple team members participate in filling out the requirements?

Yes! Multiple stakeholders across different departments can collaborate on the requirements assessment. Companies can assign specific team members to relevant sections (e.g., Finance handles General Ledger, HR handles Payroll), ensuring a comprehensive and accurate review.

Does Discover only evaluate Microsoft Dynamics Business Central (BC) and Finance and Supply Chain Management (FSCM and CE), or can it assess other ERP systems?

Discover can be used to evaluate any ERP software because it is product-agnostic and data-driven. The Microsoft ERP solutions BC and FSCM have been evaluated thousands of times using the platform, so a large data set shows how those solutions match requirements. Still, the tool provides an unbiased, data-driven view of how ERP solutions align with a company’s needs.

What happens after the Discover assessment is completed?

The results are compiled into detailed reports that include:

- Requirements fit analysis comparing business needs to ERP capabilities.

- Workflow-based view of how the ERP supports end-to-end processes.

- Rough Order of Magnitude (ROM) estimate, providing insights into implementation costs and resources needed.

How does Discover handle uncertain or unclear requirements?

If a requirement is unclear or unfamiliar, users can mark it as “Unsure”. The tool then provides an opportunity to review these items later with an ERP consultant or implementation partner for better clarity. For unique requirements, the tool allows for those to be easily added in a “custom requirements section”

Is Discover free to use?

Currently, Microsoft is funding Discover for eligible companies, making it available at no cost. However, availability may be limited to a specific time, so businesses are encouraged to take advantage of it while the funding lasts. Please see our pricing page for companies only eligible for partial funding from Microsoft.