Beyond AP Automation - The Tip of the Data Capture Iceberg

July 29, 2021

Beyond AP Automation: Uncovering the Surface of Data Capture

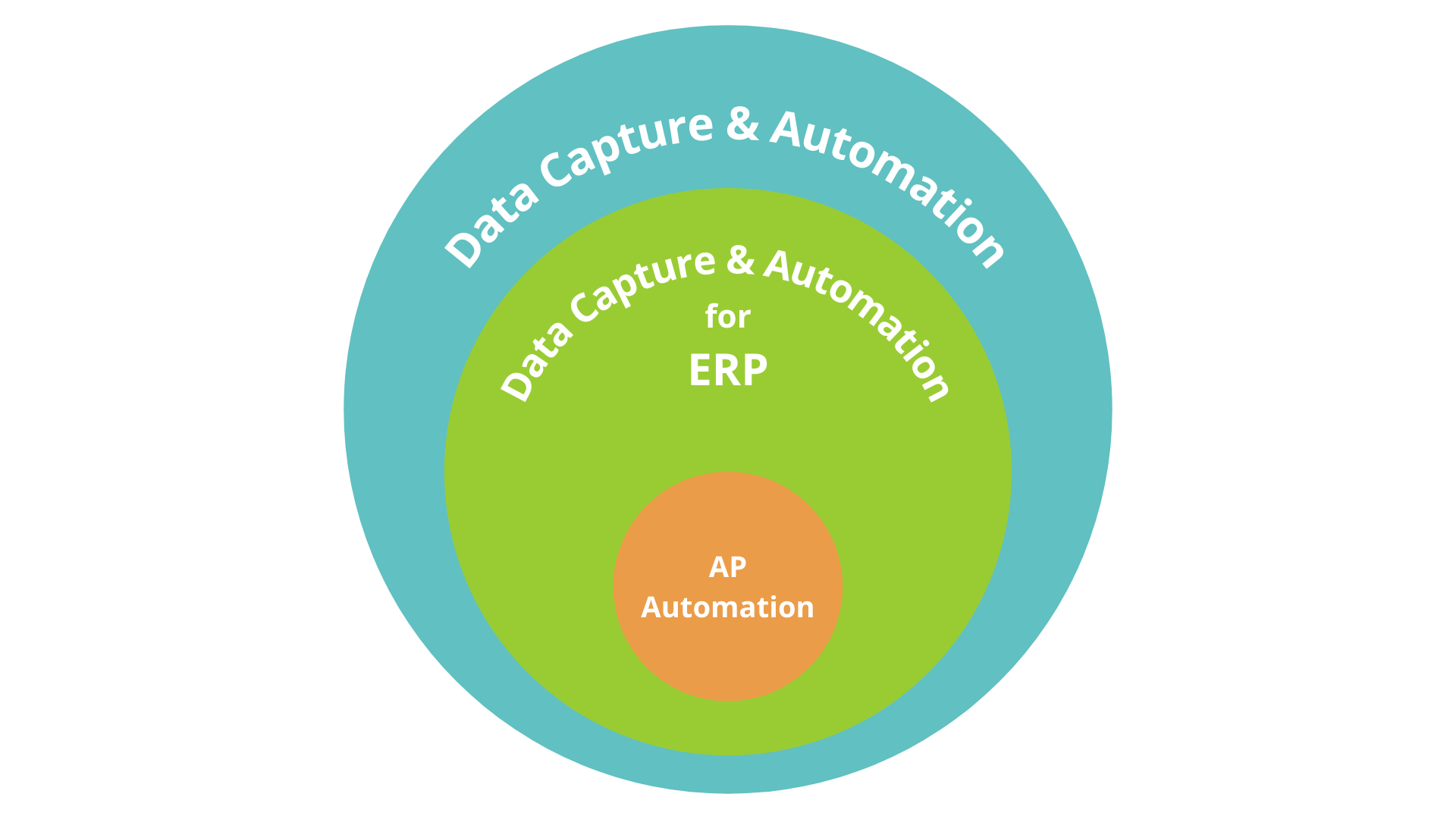

HandsFree ERP is a dramatically different approach to the data capture and automation market for Microsoft Dynamics ERP solutions. It includes AP Automation but is so much more. In the following series of blogs we lay out these differences.

Do you remember not paying attention in high school math when the subject was Venn Diagrams? Because when will you ever need those in real life? Well, today is that day!

AP automation is a minor subset of the data capture and automation industry.

What are data capture and automation? A simple description is that it is business card scanning on steroids! In the ERP world, it replaces the need to have people doing data entry work. Hence our term hands-free .

The data capture and automation market has undergone some name changes in recent years:

The interesting thing about AP automation is that it has been the only focus for vendors offering data capture and automation solutions in the mid-market ERP space. Interesting, but odd.

Interesting because Accounts Payable (AP) automation takes money out of your bank account faster. I know that is a tongue in cheek simplification because of all the benefits derived from AP automation. Still, the point is, why not bring the data capture and automation tools to bear on much more important transactions?

For example, why not speed up the customer order entry function? In the world of Amazon same-day shipping expectations, it would make logical sense that improving customer delivery would be the number one priority.

I think the reasons why vendors have focused exclusively on AP Automation solutions are simple:

Let’s drill into that more thoroughly in my next post: AP Automation – Everything wrong with existing solutions! Check it out, AP Automation – The Good, the Bad, and the Very Ugly . Peter Joeckel , President of TurnOnDynamics, a Microsoft Dynamics consultancy specializing in providing senior functional and technical resources for Microsoft Dynamics ERP.

TurnOnDynamics is the premier implementation and integration partner for HandsFree data capture and automation solutions for Microsoft Dynamics ERP clients.

AP automation is a minor subset of the data capture and automation industry.

What are data capture and automation? A simple description is that it is business card scanning on steroids! In the ERP world, it replaces the need to have people doing data entry work. Hence our term hands-free .

The data capture and automation market has undergone some name changes in recent years:

- RPA or robotic process automation was in fashion for a while because it evoked the image of robots doing data entry rather than people.

- RPA, at some point, morphed into IPA or intelligent data automation. The primary driver for that change is the requirement that everything in the software world utilizes AI or artificial intelligence. Of course, fancy name changes usually allow for higher pricing. As a prime example, accounting software was a lot cheaper than ERP software.

- Data Capture and Automation is the industry that revolves around reading documents, manual and electronic documents, and creating data that is then used anywhere as needed.

- Data Capture and Automation for ERP involves explicitly taking data from manual and electronic forms that need to be input into an accounting or ERP system.

- AP Automation specifically deals with taking invoices from vendors, again electronic or manual invoices, and capturing the data in the invoices and loading it into the ERP system without the need to type the data. Again, hands-free .

The interesting thing about AP automation is that it has been the only focus for vendors offering data capture and automation solutions in the mid-market ERP space. Interesting, but odd.

Interesting because Accounts Payable (AP) automation takes money out of your bank account faster. I know that is a tongue in cheek simplification because of all the benefits derived from AP automation. Still, the point is, why not bring the data capture and automation tools to bear on much more important transactions?

For example, why not speed up the customer order entry function? In the world of Amazon same-day shipping expectations, it would make logical sense that improving customer delivery would be the number one priority.

I think the reasons why vendors have focused exclusively on AP Automation solutions are simple:

- AP is relatively easy to automate in comparison to other business flows.

- Many vendors are enjoying success with their AP automation tools, and the market is not saturated.

- The AP automation solutions in the market are not flexible or portable.

Let’s drill into that more thoroughly in my next post: AP Automation – Everything wrong with existing solutions! Check it out, AP Automation – The Good, the Bad, and the Very Ugly . Peter Joeckel , President of TurnOnDynamics, a Microsoft Dynamics consultancy specializing in providing senior functional and technical resources for Microsoft Dynamics ERP.

TurnOnDynamics is the premier implementation and integration partner for HandsFree data capture and automation solutions for Microsoft Dynamics ERP clients.

HandsFree ERP is dedicated to supporting clients with their ERP initiatives, enabling companies to seamlessly connect users with their ERP partners. By utilizing skilled professionals, streamlined processes, and cutting-edge tools, HandsFree ERP significantly boosts the success rates of ERP projects.