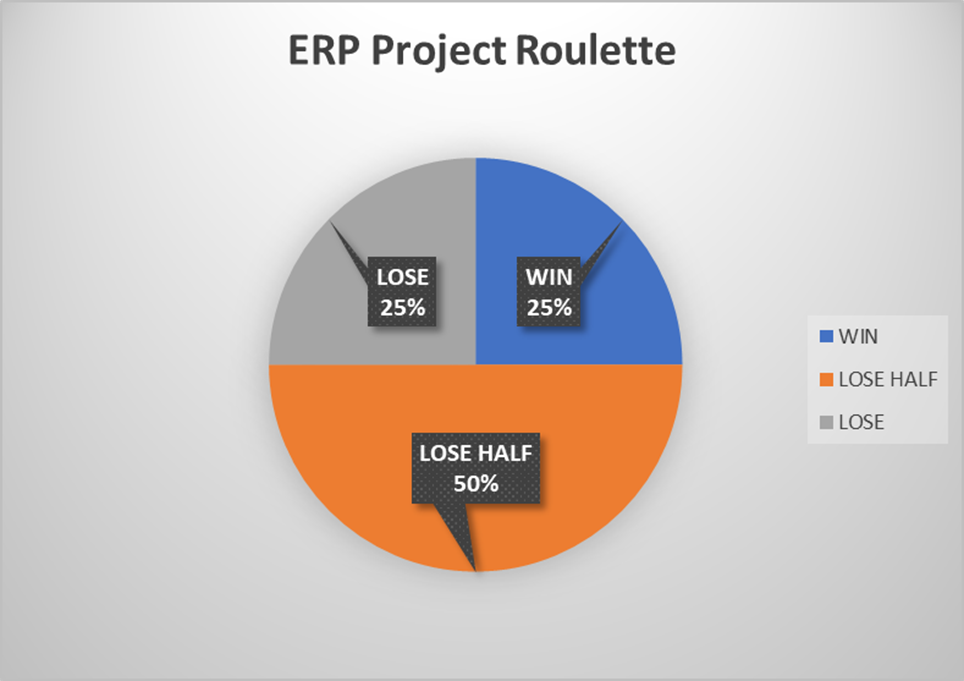

ERP Project Roulette

What Gamblers Know that ERP Buyers May Not

The ERP Project Roulette Wheel of Pain

Expected Value (EV)

When analyzing an investment, the expected value (EV) anticipates its value at some future point.EV positive indicates a positive future result for an investment decision, while EV negative indicates a loss.

Negative EV and ERP Projects

I'm just warning you: Math is ahead.

This simple but powerful concept applies to a typical ERP selection, implementation, or upgrade project.

Our basic assumptions are as follows based on industry studies:

- Twenty-five percent of projects are successful, delivering promised functionality on time and within budget. We would argue that these projects do not exist, but we will agree to this definition for simplicity.

- Twenty-five percent of projects are considered complete failures requiring a complete do-over.

- Fifty percent of projects fall into the challenged category, meaning they will incur a substantial cost increase due to a lack of delivered functionality or cost and time overruns.

Assuming a typical enterprise ERP project, our expected value for every dollar spent on that project on that project would be:

- Success: .25 x $1 = .25 cents (we gained total value for our dollar spent)

- Failure: .25 x - $1 = - .25 cents (we lost our entire value for our dollar spent)

- Challenged: .5 x $- .50 = -.25 cents (half the time, we received only a fraction of value for our dollar spent)

Adding up these possible outcomes, what is the expected value for a typical ER project?.25 cents -.25 cents -.50 cents = - .50 cents.

Conclusion

We expect to lose fifty cents for every dollar spent on an ERP project or that all ERP projects have a negative EV.This analysis suggests we should never consider starting ERP selection, implementation, or upgrade projects.This negative ERP project EV is why HandsFree ERP is leading the way with new tools, processes, and attitudes applied to these projects.

Contact us today to discuss how we can increase the odds of your ERP project having a positive EV.

Peter Joeckel

With an IE/OR engineering degree and enterprise software implementation experience starting at Price Waterhouse, Peter Joeckel has been in the business application selection, implementation, and challenged project turn-around business for over thirty years. He credits his industrial engineering degree with his search for better processes and tools to implement complex business application platforms.

Most recently, he was the lead HandsFree client advisor in the Circle of ERP Excellence lounge and speaker at the Community Summit North America.

HandsFree ERP is dedicated to supporting clients with their ERP initiatives, enabling companies to seamlessly connect users with their ERP partners. By utilizing skilled professionals, streamlined processes, and cutting-edge tools, HandsFree ERP significantly boosts the success rates of ERP projects.