Avoiding the Vodafone Trap: Data Governance Lessons for Your Next ERP Migration

Data Migration is #1 reason for Go-Live Delays

The main reason for ERP Go-Live delays is Data, and specifically Data Migration and Quality issues. Data migration mistakes can cripple operations and kill careers and even companies. No joke! This weeks episode we will use Vodafone as one of the famous data disaster examples. But we will also walk you through how you can avoid this by using the right approach and tools.

Story in short: Vodafone migrated data from seven legacy billing systems, and many records were not migrated correctly; errors went unnoticed until about a year later. Prepaid customers lost service despite having paid. AND fines totaled to £4.6 million, reputational damaged, plus revenue losses from disrupted services. Yikes!

Here’s a deeper look what happened:

- Vodafone migrated 28.5 million customer accounts and nearly 1 billion data fields from seven legacy billing systems into a single Customer Care & Billing platform

- A “small proportion” of pay-as-you-go customer accounts were incorrectly transferred, specifically, top-up credit values were not applied, leaving accounts disconnected even after customers had paid

- The issue affected 10,452 customers, who collectively lost £150,000 over ~17 months

- Vodafone failed to detect the issue promptly; the problem persisted for months before business leadership was alerted, prompting regulatory intervention and a £4.6 million Ofcom fine (£3.7 M for service failure and £925 K for poor complaint handling).

- Sales plummeted—UK revenue dropped ~11.4% (≈€54 M) in a single quarter—and customer churn rose as complaints surged to triple the industry average

Data Migration-Specific Issue:

- Automated migration tools incorrectly mapped or failed to load critical fields (e.g. PAYG balances), creating mismatches between systems.

- No validation checks or reconciliation logic flagged discrepancies between legacy and new systems.

- Dependency hierarchy errors meant some fields loaded before necessary master data, causing business logic errors downstream.

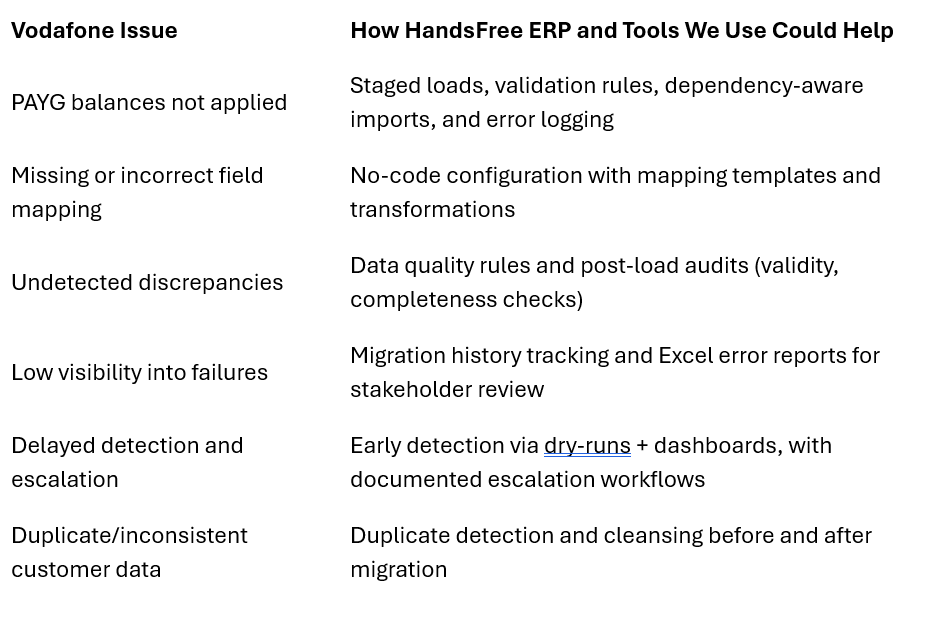

How HandsFree ERP and the Right Tools Would Have Helped

Right data migration and quality tools that we use:

1. Data Migration Studio

- No-code, model-driven tool embedded in the ERP for migration of master and transactional data, with configurable mappings and pre-built accelerator templates, speeding up mapping and reducing custom coding needs

- Ensures correct import hierarchy, so dependent transactional data (like PAYG balances) aren’t loaded before prerequisite master data (customer accounts, tariff plans.

- Migration history and error logging, with Excel reporting of failed records so stakeholders can validate and correct issues collaboratively before going live.

- Incremental execution support: run staged loads, spot failures early, optimize before full batch execution, avoiding large-scale failures.

2. Data Quality Studio / Master Data Management

- Provides data quality checks on validity, completeness, integrity, accuracy, consistency, and timeliness via configurable rules: detecting missing patterns, invalid values, duplicates, or mismatches during the migration or after initial loads.

- Duplicate detection and enrichment prevent customer record mismatches (e.g. merged accounts for distinct users).

- Web-service lookups and pattern-based validation to verify balance fields, plan codes, and numeric/format compliance.

- Supports workflows so business users can approve or correct flagged records in a controlled way.

Bottom Line

Had Vodafone employed an automated and governed migration platform, they could have:

- Caught mis-applied balances with tests and validations early.

- Ensured accurate field mappings using configurable templates and staging.

- Allowed business users to review and correct failed records collaboratively.

- Driven visibility through migration audit logs, enabling faster escalation.

- Ensured overall data integrity and consistency, reducing customer impact.

In short, such tools bake in best‑practice data migration governance, greatly reducing risk and increasing transparency, exactly what Vodafone needed to avoid the fallout from its botched migration.

✅ SUMMARY: What Vodafone Could Have Prevented with Right Help and Tools

HandsFree ERP is dedicated to supporting clients with their ERP initiatives, enabling companies to seamlessly connect users with their ERP partners. By utilizing skilled professionals, streamlined processes, and cutting-edge tools, HandsFree ERP significantly boosts the success rates of ERP projects.